A long term perspective: From success in the marketplace to full EDM rollout

1. BACKGROUND

StormHarvester and Wessex Water started working together in 2020 on a blockage detection trial in the city of Bath. Bath was chosen as the location for the trial as it has 89 storm overflows, making it a compact catchment with a high density of overflows. Over the years, this has been scaled up to include 1,500 signals.

Wessex Water chose to deploy the StormHarvester solution to gain additional insights from their existing network of wastewater sensors. Specifically, the company wanted to test the ability of AI (machine learning) to:

1. Accurately detect blockages

2. Create smarter control room alarms

Results from the initial trial:

- The capability to reduce event duration monitoring alarms by 97%.

- StormHarvester detected over 60 early blockage formations in real time, at least 2 of which would have caused significant pollution incidents (CAT 3 or worse) if it was not for these alerts.

- Over 60 telemetry and sensor faults were also detected in real time.

2. BEYOND THE TRIAL

Based on the value brought by the StormHarvester alerts, Wessex Water decided to rollout across the wider wastewater network, and the system now runs over 1500 signals.

As well as detecting sewer blockages, Wessex Water are experiencing benefits around:

• Device reliability. Wessex Water now have better visibility of equipment that had stopped communicating or failed and also when equipment had started to behave differently (indicating either a failure or a physical change at site)

• A new failure mode with EDM equipment that Wessex Water were not previously aware of.

• Using predictive technology to proactively inform customers:

– Poole Harbour: A designated shellfish water – advising customers where water qualiy may impact shellfish activity.

– Warleigh Weir: Flagging risk where water quality may impact swimming.

“StormHarvester has helped Wessex Water over the last two years to almost completely eliminate preventable pollutions from storm overflows. The StormHarvester team are great to work with and continue to push the boundaries of how we use and benefit from our data.”

Rich Evans Regional Network Monitoring Manager

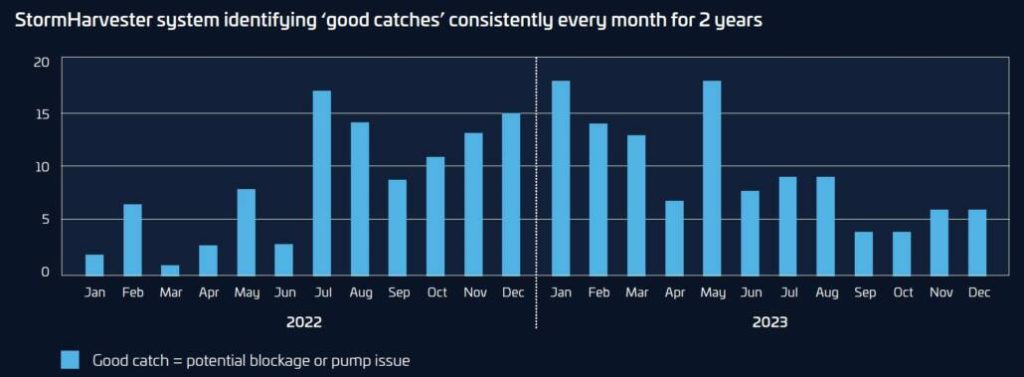

3. GOOD CATCHES

A good catch to an issue that has been identified and resolved that may have caused a spill or operational issue if not picked up.

These issues are primarily:

• Blockages

• Pollution evidence gathering

• Pump and control issues

BLOCKAGE EXAMPLE

- 7 May – Sewer level breaches threshold. StormHarvester system generates an alert to Wessex Water.

- 8 May – Utility crew attend site and remove blockage. No impact to customer or environment as blockage is identified early.

- 9 May – Sewer level returns to previous behaviour within thresholds.

- 11 May – High rainfall event increases thresholds. This is expected behaviour – no threshold breached and no alert sent.

4. HOW THE PARTNERSHIP HAS EVOLVED

Over the 4 year collaboration, the StormHarvester and Wessex Water teams have been able to build close working relationships.

By establishing a multi-functional team and running fortnightly meetings, any outstanding issues are quickly resolved. With adopting this new technology, Wessex Water created a new team, specially trained to manage the incoming data. The team has continued to grow as more sites were onboarded and the level of data increased.

The benefits of the collaboration between StormHarvester and Wessex Water are regularly reported on in Wessex Water’s customer magazines (Spring-Summer 2023 edition – page 14 and Autumn 2023 edition).

Looking to the future, Wessex Water are now able to:

- Build a long-term strategy around the use of smart technology (StormHarvester features throughout the Wessex Water PIRP – Pollution Incident Reduction Plan – page 9).

- Gain a better understanding of the wider network, and explore issues like Inflow and Infiltration, and Flow to Full treatment alerting.

- Reduce preventable pollutions.

- Better understand where to prioritise their network investments.